|

CARBON BLADES

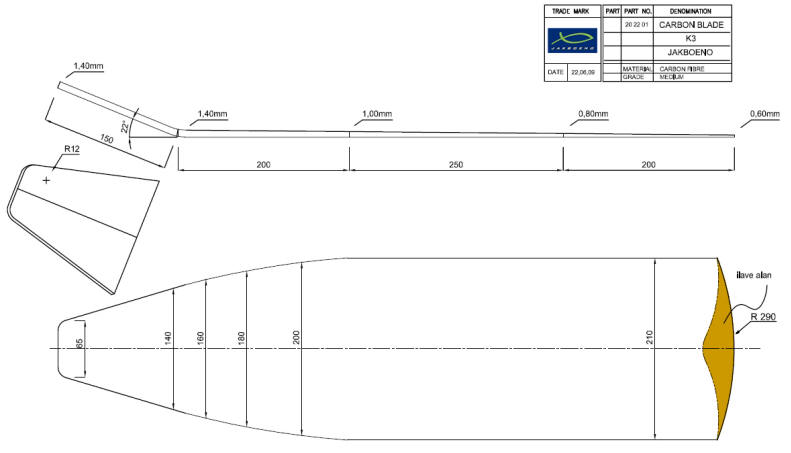

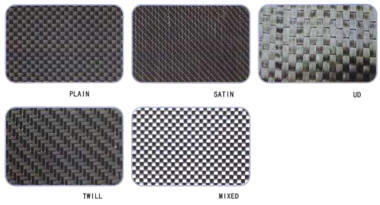

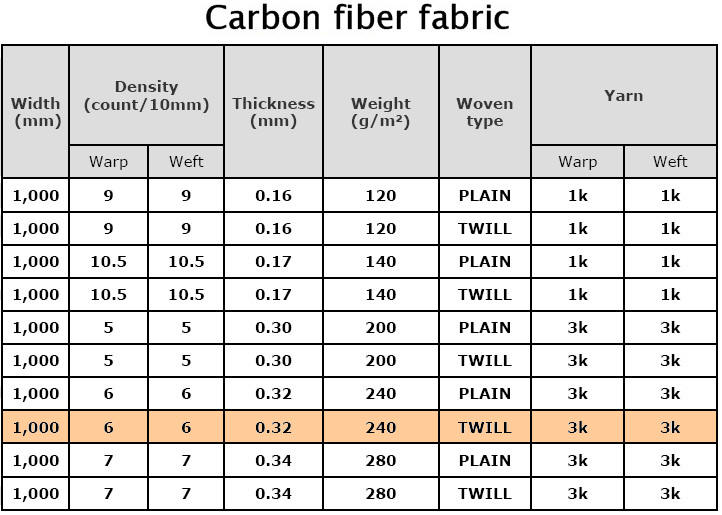

Carbon fiber fin blades are manufactured with 3K Twile weaved carbon fabric. Cabon fiber blades are ideal for underwater as they are characterized by their optimum efficiency regarding lightness and their high yield of performance. JAKBOENO fin blades are produced using carbon, carbon-kevlar and glass fibers in three different thicknesses (soft-medium-hard). All blades are hand crafted. The patterns and writings are off-set transfer printed to specific fabrics first; the fabrics are then covered with epoxy resine in steel molds into fin blades. This process enables the patterns to be considerably resistant to abrassive underwater environment. The thickness of the fin decreases from 1.40 mm to 0.60 at the tip. Unlike the usual layer peeling method of fin thinning, this gradient in JAKBOENO fins is obtained in the molding process making the fins again more durable.

The fin blades are manufactured to

attach to the foot pocket at the ideal ergonomy of 22o

The epdm rubber side bands are inverse-T shaped to allow easy

fitting to almost all foot pockets. |

|

|

|

|

GLASS FIBER BLADES

Glass fiber blades are produced by combining glass fiber with epoxy resin. These bladesí durability along with their suitable price makes them a good choice for shallow and mid-depth diving. The Reef Green camu patterns and writings are off-set transfer printed to specific fabrics first; the fabrics are then covered with epoxy resin in steel molds into fin blades. This process enables the patterns to be considerably resistant to abrasive underwater environment.

|

|

|

|

|

GENERAL INFORMATION

JAKBOENO fin

blades are produced using carbon,

carbon-kevlar and glass

fibers in three

different thicknesses (soft- All blades are hand crafted. The patterns and writings are off-set transfer printed to specific fabrics first; the fabrics are then covered with epoxy resine in steel molds into fin blades. THis process enables the patterns to be considerably resistant to abrassive underwater environment.

The thickness of the fin decreases from 1.40 mm to 0.60 at the tip. Unlike the usual layer peeling method of fin thinning, this gradient in JAKBOENO fins is obtained in the molding process making the fins again more durable. The fin blades are manufactured to attach to the foot pocket at the ideal ergonomy of 22o .

The PVC side bands are inverse-T shaped to allow easy fitting to almost all foot pockets. The convex form of the tips increase the surface area of the fin by 8 %.

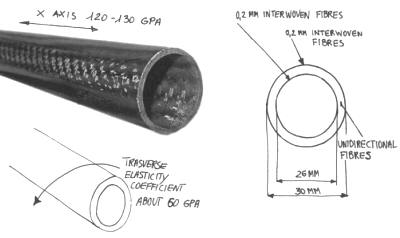

Information on Carbon Fiber Carbon fiber is characterized by its durability, lightness, resistance to chemicals and abrassions and flexibility. These characteristics make carbon fiber an ideal material for fin blades and spear guns.

Information on Carbon-Kevlar Fiber Kevlar Fiber is used in manufacturing protective textile such as bullet proof fabric. Carbon fiberís flexibility and lightness and kevlar fiberís extraordinary strength come together in carbon kevlar fiber making it a great material for fin blade production.

Information on Glass Fiber Glass Fiber is produced by forming 0,005-0,020 mm threads from glass molten at 1600 oC. Its ability to perfectly combine with epoxy resine along with its suitable price makes glass fiber a commonly prefered material for fin blade manufacturing.

|

|

|

|

|